The Pianist as Engineer

- Piano Design

- Piano Manufacturing

- Digital Piano Player System Design and Installation

- Player Piano System Design and Installation

- Electronic Tuning Device Design and Use

- Reconditioning, or Action Rebuilding

- Touchweight Analysis and Correction

- Action Replacement

- Restringing

Electronic Tuning Devices

Ever see somebody plop some form of this illustration on your piano, open it up, remove the music desk, whip out a tuning hammer, and start plinking away without hardly playing a note?

This, unfortunately, is becoming the greatest demonstration of competence for pianists by the piano tuner. How?

A big reason is that so many piano technicians are bad artists and piano players. Another, is that playing and tuning pianos aurally is so hard. Notwithstanding, it is not that so many piano technicians are better engineers than artists, or good engineers; actually, most piano manufacturers and retailers complain quite the opposite is the case with piano technicians. Still, all too frequently, piano performers, teachers, and composers, have a bad experience with an aural technician, develop an understanding of how prevalent bad artists are in piano technology, and only are relieved that the obligation to rely on the artistry of the piano tuner has effectively been eliminated, by electronic tuning devices, as the piano technician pretends to be the engineer in the room, rather than the one who designed the piano. The artistry of the piano technician is reduced to modifying the sound of the voicing, which terrifies the pianist all the more, i.e., manipulating the density of the hammer with solvents and needling! How is the piano technician, particularly one with no ability to play, going to know how a piano is supposed to sound, if not regularly tuning by ear, not eye? Should the pianist be more comfortable with the aural tuner changing hammer density, or the visual tuner?

In general, piano tuners, performers, teachers, and composers, are bad engineers, and woodworkers; capability for piano maintenance has been rejected as a possibility, because of this, for the performer. Should this be so? Not that the pianist is so great an artist. No, the possibility that many pianists would undertake the task of tuning, is only possible, with such a device, engineering the tuning process. So the deficiencies of both pianist and tuner appear within their own expertise in the face of the ETD. The piano technician is a bad artist as it relates to his or her profession, the pianist, a bad artist as it relates to tuning, generally considered not to be, a tuner. The piano tuner as artist, i.e., aural tuner, not visual, has effectively been hedged out of the environment in this situation, because of how daunting a challenge tuning aurally is for all parties considered.

The dissection of piano technology from the work of the pianist has been detrimental to the piano industry as a whole, and extends far beyond the virtual explosion of electronic, or visual, tuning in the industry to the specialization of piano technology in general. It is no coincidence that research and development in the piano industry simultaneously went into decline as the expertise of piano technology began to develop and to crowd out the artists themselves from taking on the task of piano tuning and rebuilding. How do we know how a piano is supposed to sound without playing and tuning aurally, not visually?

There are many stumbling blocks, scandals, specialization has created for the piano industry in general, only a few of which could be touched on here.

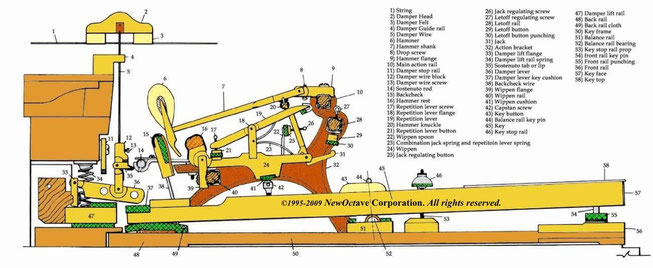

Action Rebuilding

Action rebuilding has largely been transformed into an operation in the tristate area and elsewhere that defies some basic principles of both the geometry and the touchweight components of

an action as designed and produced by almost all surviving and obsolete piano manufacturers. Many technicians neglect significant aspects of piano maintenance, improving

the sound, not the feel of the piano, and reducing the cost to the consumer of such work, i.e., the pianist, by creating unnecessary expense. Feelings are important, no doubt. On the other

hand, knowledge of this distinction between sound and feel is so alien with pianists in the age of specialization that some will confuse an alteration of sound for one of feel and

vise versa, which should tell us something it doesn't. This has largely happened because of specialization discussed on this site within a trade that once was not sliced into insignificant

bites and pieces. The manufacturers have a goal in mind, and though a veneer of cooperation between piano technicians and manufacturers has been created through schools, this patina of

information sharing has generally failed to bring about recognition for some of the most fundamental characteristics of the parts in a piano action and why manufacturers once designed them this

way.

E.g., virtually all modern grand hammer manufacturing and engineering is not for the purpose of creating static weight for a hammer in action design and rebuilding, but one of dynamic weight, for the purpose of maintaining a pleasing sound, not touchweight. This should be clear when considering the forms hammers once existed on pianos in history where this may or may not have been the case. It has generally been understood that the modern grand hammer has for over a century been something with a weight that is constantly in flux, i.e., something that will constantly be reduced in weight as hammers are filed for continued use. It is estimated that each filing removes approximately 5 grams in touchweight, significantly and irregularly altering touchweight for the pianist. But piano maintenance and use has in this age been so strictly demarcated, that piano technicians are more concerned with maintaining the weight of the hammer than the way the piano sounds, while the pianist has been forced to accept the terrible sound of a piano for the sake of weight, because some technicians have become so preoccupied with touchweight that they will not file hammers rather than make compromises to most pianists, that are negligible at best, in most preparatory situations. As for piano pedagogy in performance, most pianists, though sensitive to these changes, are trained to compensate for these alterations, all while many piano technicians try to convince them they are not and must employ technicians to coddle the pianist through such modifications in touchweight that are by the most competent technicians, uniform in scope.

This is just one of the many follies that has arisen in piano maintenance and use due to the coeval separation between pianist and technician, and the illusory reconciliation between technician and manufacturer. It also plainly reveals the engineering incompetence of piano technicians in isolation/those who don't play, as that for such a goal to be realistic, old models for hammer production, such as covering hammers with a more durable material, would have to be researched and reintroduced, and for the most part, are not in any meaningful way being so for all the enthusiasm that has been demonstrated in the field about hammer weight as a static component of action geometry and touchweight. The factories and technicians demonstrate this kind of convoluted agenda with a static standard for hammer weight on part of the technician, and a dynamic one by the manufacturer and designer. And so the musician is punished for his or her ignorance in the matter.

This is just one example of the wrongheadedness of irregular specialism in the field.